Thermography Electrical Switchboard Thermography, or Infrared Scanning, is the best way to prevent disaster

Get a Quote

Overview

What a lot of people do not realise, is that a major by-product of energy is heat. This can cause a massive interruption to daily business when this heat exceeds a certain level and results in a fire or similar breakdown of the supply. The best way to prevent your business from one day being profitable and the next day being a pile of ashes and mountain of insurance claims to fill out, is to routinely do an Electrical Infrared scan or Thermography inspection on your electrical supply terminations and Switchboards.

Information

What is Thermography?

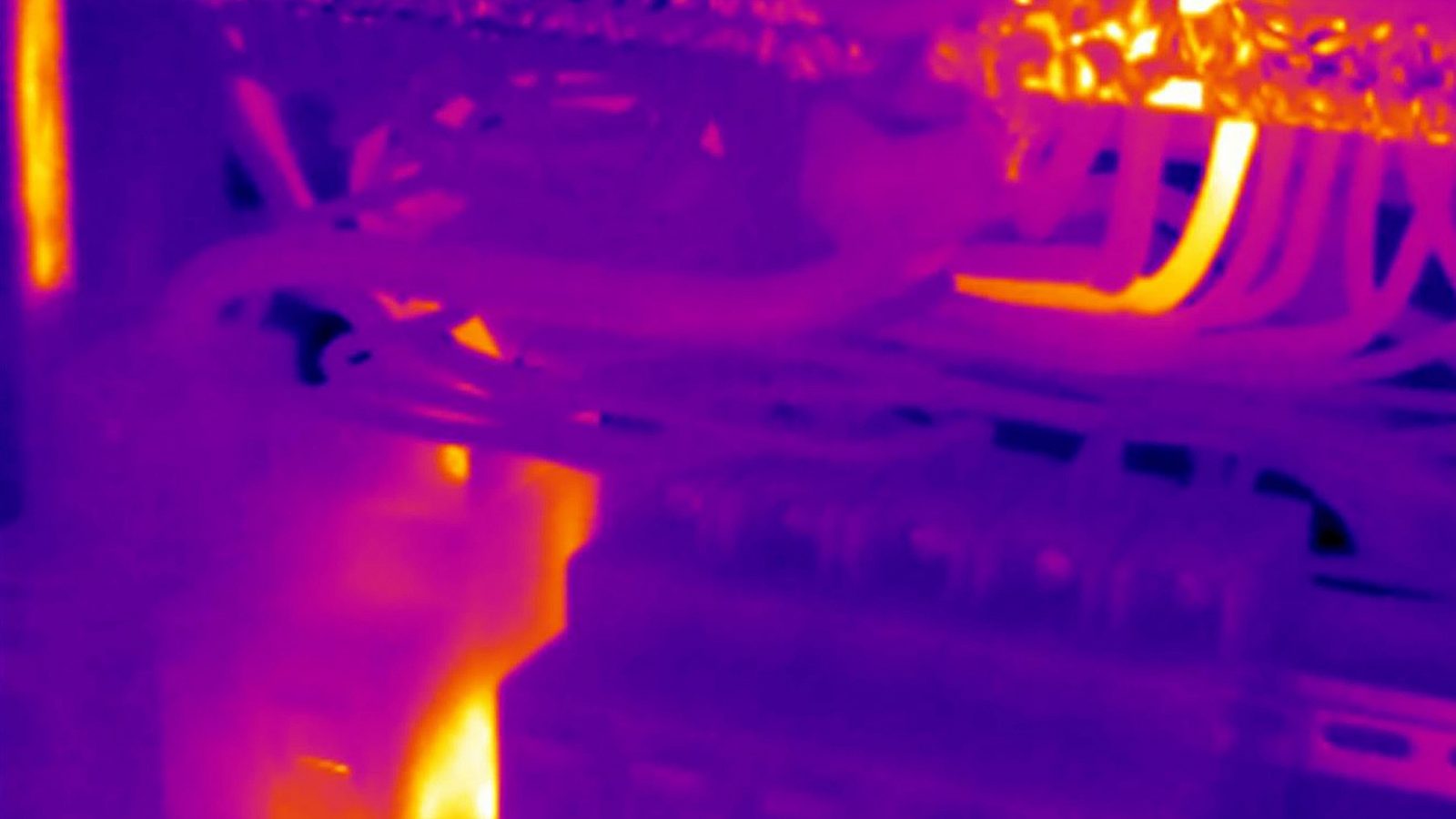

Thermography is taking a thermal image of an electrical installation (generally a switchboard under load) and identifying any hot spots, poor terminations, loose connections etc. In most cases faults / hot spots cannot be detected by the naked eye and require the use of a special camera that provides a thermographic image of the area scanned.

This allows an electrician to reduce the risk of any major breakdown, fire etc. that may occur because of overheating at a particular point or connection.

This also helps in identifying overloaded circuits or cable sizes that are too small to carry load capacity.

What do I get from ATTS after the scans are completed?

- A thermo-graphic image of your switchboard under load

- A digital image of the equipment that the scan was done on

- Loads across the three (3) phase. (This helps to detect an in balance of loads which can cause extreme high temperatures on one phase and not on another).

- A report with all images displayed (Thermographic and digital)

- A fault report if any faults are found

- Recommendations on corrective action that is required

- And most importantly peace of mind that your business will not be in ashes due to an electrical fault

Services

ATTS have been performing this service on a national basis for the last 14 years

We have up to date calibrated equipment capable of imaging and recording excellent clear images that assist in identifying the potential weak point in an installation

We can provide a report & quote for repairs

ATTS are qualified electrical contractors and cannot just identify issues but also offer qualified advice and competitive quotation for repairs

Thermal issues that require urgent attention can in some cases be rectified on the spot

FAQs

No. This is not a compliance or mandatory inspection under any current standards, but is requested now by a lot of insurance companies that want to reduce exposure to the client and themselves in interruption to business activities.

Some insurance companies will reduce your premiums if a regular / yearly thermo or infrared scan is done on your electrical switchboards.

Link to this articleThe cost varies from customer to customer. Contact us for a quote for your business.

Link to this articleThermography scans (infrared scans) should be done on all electrical sub mains, mechanical switchboards, electrical switchboards, power factor correction units and any other large electrical installation.

This should be done when the all the equipment is under maximum load or generally we recommend in the hotter part of the year (Oct – March).

Link to this articleThermographic /infrared scanning should be one part of a preventative maintenance regime that is incorporated in your yearly task the same as testing of your fire equipment. It will detect faults before they become major issues and headaches for your business.

Link to this articleNo. Thermographic / Infrared scanning does not require a shutdown of your electrical switchboards and is best performed when max load or usage is occurring.

Link to this article

Get a Quote

Or just ask a question...

Related Services

Prevention

Power Factor Correction

Maintaining Power Factor Correction Units ensures the money you save is protected

Prevention

Uninterrupted Power Supply (UPS)

Testing and maintaining your Uninterrupted Power Supply (UPS)